0311-9484072

Phone number

info@pakistanbricks.com.pk

Email address

51 CCA Khayaban-e-Amin, Block C Khayaban E Ameen, Lahore, 54810

Phone number

Email address

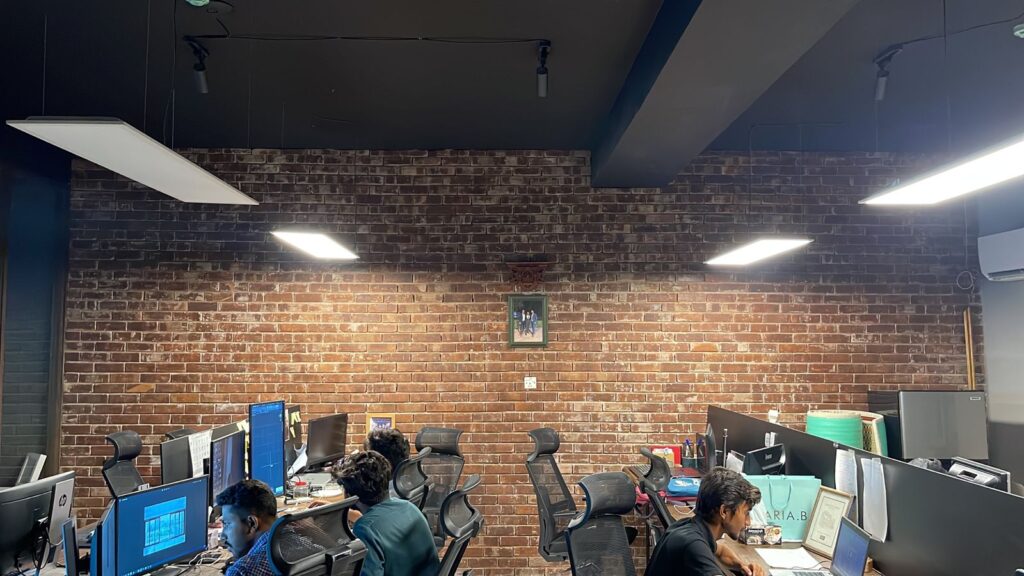

With the decades of experience in bricks & gutka manufacturing, we are now offering the renovation and construction services in Lahore.

With the zigzag technology, we are offering top quality bricks manufacturing facility with the affordable brick prices in Lahore for our customers.

Pakistan Bricks & Construction Solutions is serving our domestic and commercial clients as the best construction company in Lahore for a couple of years

Are you going to start your construction project? We are with you. Call at 0311-9484072 to get latest red clay brick prices in Lahore Pakistan.

Get your Projects Completed with Pakistan Bricks’ Premium Brick Products & Construction Services in Lahore

Our Top Client

Don’t Compromise on the quality, chose only Pakistan Bricks because:

Get the most competitive grey structure construction rates in Lahore without compromising on quality. Pakistan Brick & Construction Solutions has successfully delivered many grey structure construction projects on time and within customer’s budgets.

Transform your space with Lahore’s top home renovation experts. From modern upgrades to complete makeovers, we bring your vision to life with precision and style. We have expert team of interior & exterior designers to renovate your homes.

Tired of searching for reliable construction companies in Lahore, Pakistan? Your search ends here! Pakistan Brick & Construction Solutions is your trusted partner for quality, affordability, and excellence for all your construction needs.

As the leading construction & brick company in Lahore, we have completed many residential & commercial construction projects with 100% customer satisfaction.

If you are worried about the selection of quality bricks manufacturer & suppliers of Bricks in Lahore, just give us a call. We’ll guide you through the whole process of brick selection. Save Money & time for your future. Drop us a query below:

Bricks are the most important construction material and the quality of bricks ensures the quality of construction. Mostly there are the following types of bricks in Pakistan commonly used for the construction of houses, commercial buildings, plazas, hospitals, etc. They include burnt clay bricks, engineering bricks, concrete bricks, and fly ash clay bricks. We offer the most economical bricks rate in Lahore with wide range of bricks including Awwal, Doum and Khingar eent readily available at our Bhattas

The different types of bricks are used for different purposes. For instance, burnt clay bricks are best for making foundations, columns, and masonry walls. Sand lime bricks are used to make pillars, walls, and for ornamental purposes. Moreover, engineering bricks are used in the lining of furnaces chimneys, and to lay the foundation of buildings. Concrete bricks are the strongest of all and are manufactured using different pigments. They are utilized in the construction of fences and brickwork for the walls.

This is the Paksitan Bricks Recent Projects about Best Quality Bricks in Pakistan.

(All Gutka sizes are 9 inches in length)

| Sr. No. | Size (in inches) (H × T × L) | Remarks / Usage |

| 1 | 1.5″ × 2.25″ × 9″ | Slim face – clean finish |

| 2 | 2.25″ × 2.25″ × 9″ | Standard size – most commonly used |

| 3 | 3″ × 2.25″ × 9″ | Wider face – more visual impact |

| 4 | 1.5″ × 3″ × 9″ | Extra thick – sturdy appearance |

| 5 | 1″ × 2.25″ × 9″ | Very slim – ideal for detailing work |

| 6 | 1″ × 3″ × 9″ | Slim and thick |

(All Gutka sizes are 9 inches in length)

| Feature | Gutka | Paint | Ceramic Tiles | Travertine |

|---|---|---|---|---|

| Durability | ✅ Very high, lasts decades | ❌ Peels/cracks in few years | ⚠️ Chips/breaks easily | ⚠️ Porous, needs sealing |

| Weather Resistance | ✅ Excellent for heat & rain | ❌ Fades & peels in sun/rain | ⚠️ Slippery in rain | ❌ Absorbs moisture, stains easily |

| Maintenance | ✅ Minimal, occasional wash | ❌ Frequent touch-ups needed | ⚠️ Grout needs cleaning | ❌ Requires sealing & polishing |

| Aesthetic Longevity | ✅ Rustic look improves over time | ❌ Fades, looks dull over time | ⚠️ Trends change quickly | ⚠️ Can look worn if not maintained |

| Eco-Friendliness | ✅ Natural clay, no chemicals | ❌ Chemical-based | ⚠️ Manufactured with energy use | ⚠️ Natural but imported |

| Breathability | ✅ Allows walls to breathe | ❌ Traps heat and moisture | ❌ Non-breathable surface | ❌ Can retain dampness |

| Cost-Effectiveness | ✅ One-time smart investment | ❌ Repainting needed regularly | ⚠️ Installation & breakage cost | ❌ Expensive material + upkeep |

| Slip Resistance | ✅ Naturally textured surface | ✅ Not applicable | ❌ Can be slippery when wet | ❌ Very slippery unless textured |

| Design Impact | ✅ Timeless, classic & premium | ⚠️ Plain, limited visual impact | ✅ Modern, but common | ✅ Elegant, but costly and delicate |

| Local Availability | ✅ Readily available in Pakistan | ✅ Easily available | ✅ Available but standard styles | ❌ Often imported, limited choices |

The price of bricks varies across different cities in Pakistan due to factors such as raw material costs, labor expenses, and regional availability. South Punjab, including cities like Multan, D.G. Khan, Bahawalpur, Rahim Yar Khan, and Lodhran, generally offer more affordable housing options compared to other regions

Other provinces—Sindh, Khyber Pakhtunkhwa (KPK), and Balochistan—have their own pricing structures influenced by local economic conditions. Meanwhile, major urban centers like Lahore, Islamabad, Rawalpindi, Gujranwala, Faisalabad, Sahiwal, Khanewal, Peshawar, and Quetta also have varying brick rates depending on demand and supply.

If you’re planning a construction project, it’s essential to consider:

Understanding these factors will help you make an informed decision based on budget and quality requirements.

Bricks are 1 of the most popular building materials in the construction industry due to their aesthetically pleasing appearance and durability. They come in various types of bricks, each designed for specific applications. Some are reinforced for strength, while others prioritize visual appeal. Below are the main categories of bricks available:

These are the most fragile bricks, also known as unburnt bricks, and are mainly used for decorative purposes. Made from clay, they are molded and dried in the open air, making them less durable than other types.

Made from sand, cement, coarse aggregates, and water, these bricks can be customized in size and manufactured on-site. They are versatile and widely used in modern construction.

Composed of sand and lime, these bricks are known for their aesthetic appeal and are often used in architectural designs.

Manufactured using fly ash and water, these bricks offer superior resistance to freeze-thaw cycles. They are lightweight, water-resistant, and highly durable, making them perfect for thermal insulation.

These are fired in kilns and classified into four grades:

First-Class Bricks – Made using table-molding and fired in kilns, these are the highest-quality bricks. They are extremely strong and long-lasting, ideal for permanent structures.

Second-Class Bricks – Produced through ground-molding, they have an irregular shape but are still durable. They are kiln-fired and rank as the second-strongest bricks.

Third-Class Bricks – Similar to unburnt bricks, these are weak and best suited for temporary structures. They are ground-molded and burnt in clamps, making them water-sensitive.

Fourth-Class Bricks – These are low-quality bricks, often crushed into powder and mixed with concrete for reuse.

Our excellent and fast paced services are unparalleled in providing bricks rates in Pakistan. The project management and quality control teams are highly professional and work as per your needs quickly. Our bricks are of top-notch structure and quite economical. You can have the latest brick price in Pakistan.

Molded bricks are made of soft clay which has a lot of water content. They are then put in specific molds. The mold is first lubricated with sand or water, and then the brick mixture is filled in them.

The dry press process is used to make the best and the clay has very low plasticity. We use a minimum amount of water to make pressed bricks.

Brick manufacturers then dry the bricks to give them a perfect setting and shape. Initially, the bricks are placed in the sun to remove excess water. Afterwards, they put the bricks in air dryers with controlled temperature and humidity.

Firing means burning or cooking bricks in a kiln at high temperatures. Brick companies create bricks by putting them in the kiln for about 10 to 40 hours.A tunnel kiln is used in which they load the bricks and keep them covered to retain the heat inside

If you need help selecting the best bricks for construction, PakistanBricks.com.pk can guide you. We provide high-quality bricks in the ideal shape and texture, ensuring maximum durability and cost-efficiency.

Cooling is the most important part of manufacturing bricks in Pakistan. After the bricks are completely cooked and the temperature reaches its peak, the kilns are then turned down. The times of cooling depend upon the type of kiln. In a periodic kiln, the time is 5-25 hours & for a continuous kiln, the cooling time is about 10 hours.

We make the best bricks in Lahore. We have experts for creating and surveyors for accessing the quality of bricks. Now you can have a top-notch construction with our premium bricks. We offer the best bricks price in Pakistan. From material selection to processing and making, every aspect is professionally controlled.

The cost of a grey structure in Lahore ranges between PKR 2,560 to PKR 2,813 per square foot. For example:

Note: These are indicative rates that may vary Call now for updated rates.

A grey structure includes:

✔ Load-bearing structure (columns, beams, slabs)

✔ Brick masonry walls

✔ Basic plumbing & electrical conduits (no fixtures)

✔ Rough flooring (no tiles/finishing)

Note: These are indicative rates that may vary Call now for updated prices.

Note: These are indicative rates that may vary Call now for Updated Prices.

Alternative: Fly ash (used in eco-friendly bricks).

Approx. 5,000–6,000 bricks for a 1-marla grey structure (varies based on wall thickness).

50kg bag: PKR 1,400–1,600 (brand-dependent).

Note: This rates are indicative Contact us for Latest rates